Learning a musical instrument can be an immensely powerful tool for a child’s development and education, but this is all too often a privilege only available to those who can afford it. Research shows that children from lower socioeconomic backgrounds continue to be significantly disadvantaged compared to their more affluent peers in this area (ABRSM, 2014), and players of orchestral instruments in particular often face the highest barriers for entry, limiting their demographics further. This lack of access and diversity has been identified as a major factor contributing to stagnation in this area of music (RPO, 2019).

Celli is the new cello for everyone.

This project aimed to democratise access to a musical education by redesigning the cello to be more affordable, adjustable, accessible and appealing. Consideration of modern materials and manufacturing techniques from the beginning of the design process allows drastic cost reductions while maintaining sound quality. It also allows Celli to be adjustable, and to grow with a child all through their musical education.

Combined with the improved hardiness of the instrument, these cost and flexibility benefits are ideal for beleaguered music services, and provide great opportunities for inclusive group teaching.

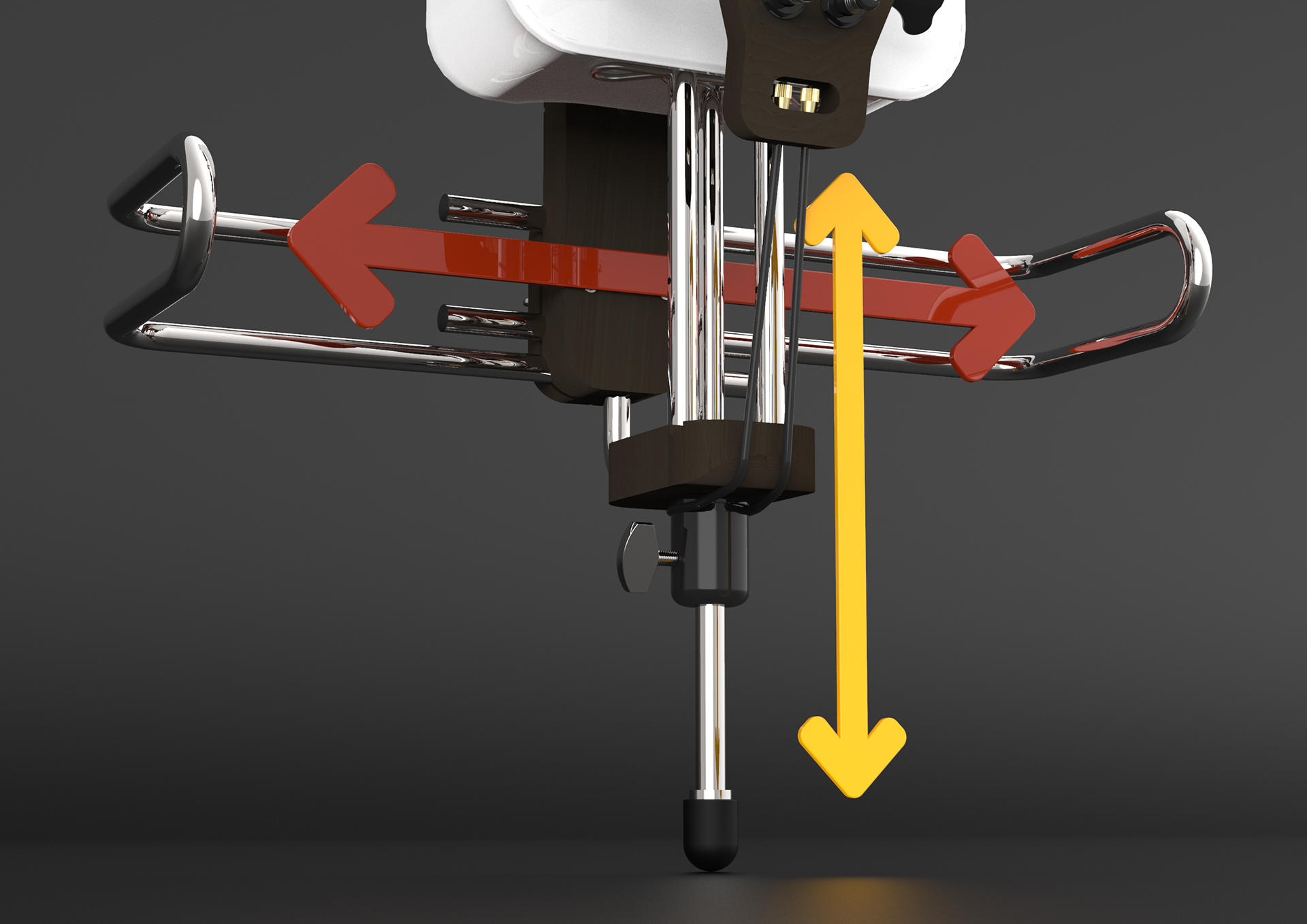

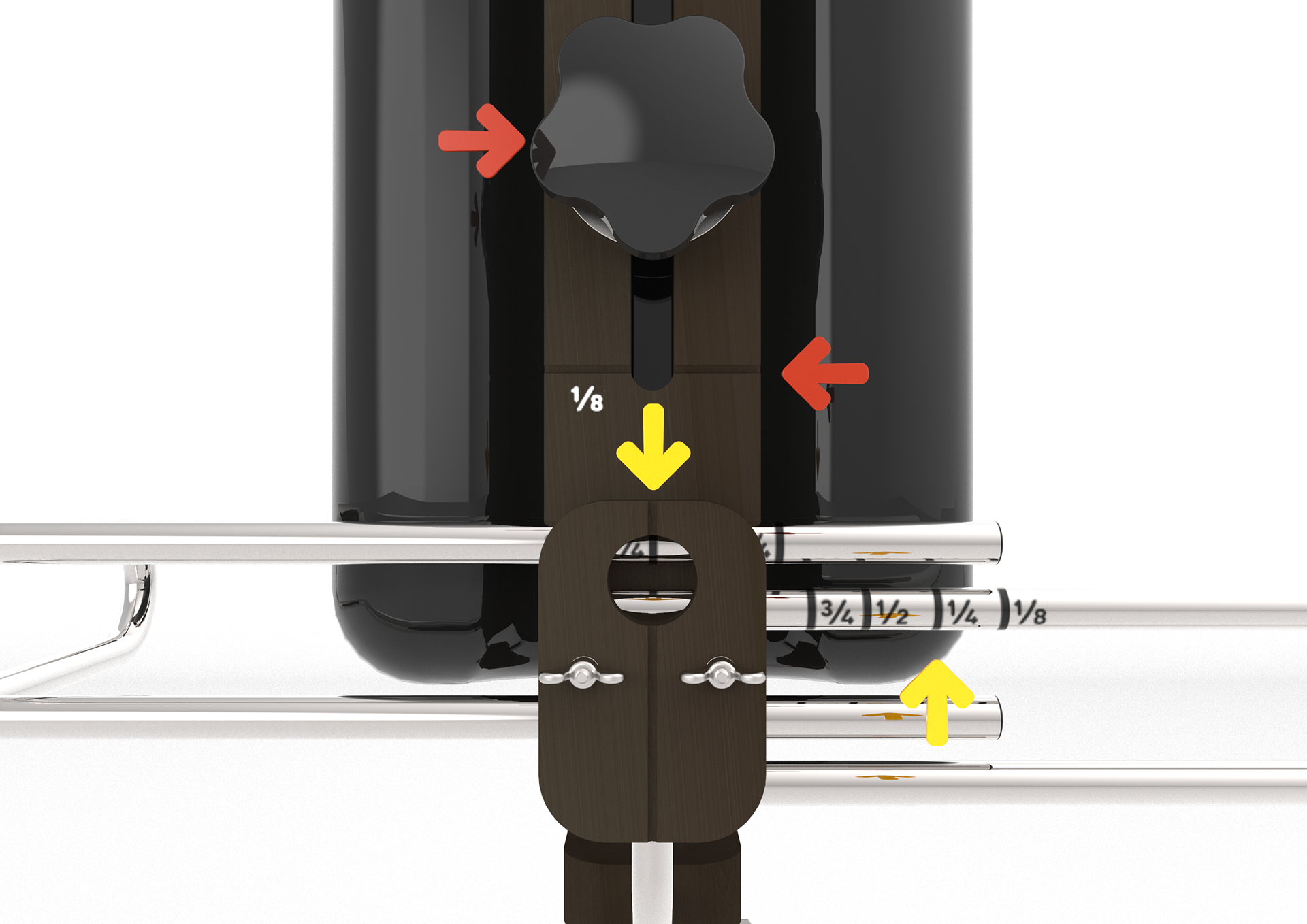

Adjustability

The neck length, body length and leg rest width are all adjustable, allowing the user to adapt the instrument to fit them. All adjustments are clearly labelled, allowing changes to be made simply by inexperienced parents or students, without expensive servicing by a luthier. This also reduces the likelihood of a young musician giving up playing when forced to change size, either from lack of effort or availability.

Affordability

The initial target market price for Celli is £119.99, with a targeted reduction to £99.99 once the production batch size increases. That is the equivalent of 6 months typical rental, for an instrument that could last a decade before being resold. Traditional materials have been replaced for modern ones which have appropriately similar physical and tactile properties, but can be produced much cheaper, faster, and more consistently.

Accessibility

Celli is a fully acoustic instrument, not electric. It is designed to allow a young musician to have access to the same musical education as one of their peers with a traditional instrument, from orchestra and ensemble performances to board certified music exams. It is designed to be the closest possible simulation of a traditional cello, so a Celli player could transition onto a traditional instrument as if they had always played one.

Appeal

The fun aesthetic is designed to be appealing to young people, in the same way an electric guitar is when compared to an acoustic one. The styling combined with the available colours of yellow, deep red, black and white have been chosen to provide a balance between the new and the familiar, traditional design cues, helping appeal to experienced cellists and educators. By introducing new demographics to this area of music, it paves the way for the creation of new and exciting music, activities and self expression, as well as easier access to what already exists.

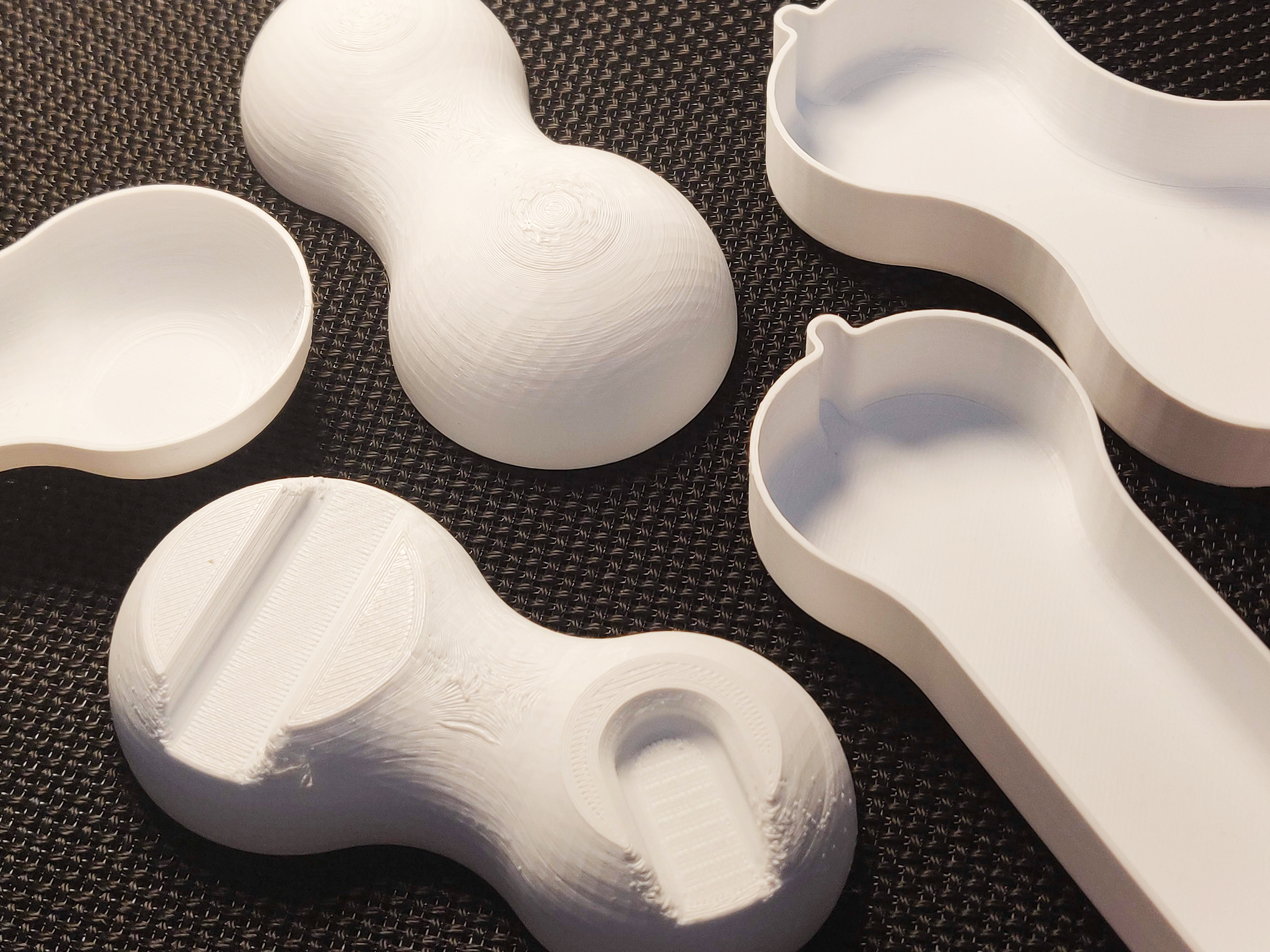

Prototyping

In order to develop a deeper understanding of materials and the important factors of cello design, several playable prototypes have been built, largely based on a test rig constructed from a broken ½ size student cello. The rig was designed to mount different materials and body shapes to, in order to study their acoustic properties, using the chassis as a control variable. This allowed experimentation with various materials, including polypropylene and PVC, and different body shapes and structures.

Form and Technical Development

Rapid prototyping and CAD modelling has been used extensively when developing the final product, helping to realise a form that is both aesthetically interesting but suitably traditional so as to be accepted by the industry. Such prototyping has also aided the realisation of the necessary touchpoints in order to accurately simulate a traditional cello. CAD modelling in Solidworks also helped to resolve the mathematical problems surrounding the instrument, allowing the creation of accurate geometry for all four sizes of instrument.