Made in Brunel is a unique student-led programme that promotes the design talent of Brunel University London through collaboration, networking and events both internal and external. Each year a team of students volunteer for Made in Brunel roles on top of their degree work. For the 2019/20 academic year I took on the role of Publications Manager. Alongside my colleague Charlie Boyle, this involved producing brochures, posters and publicity material for events and most importantly the end of year book, We Are Made in Brunel.

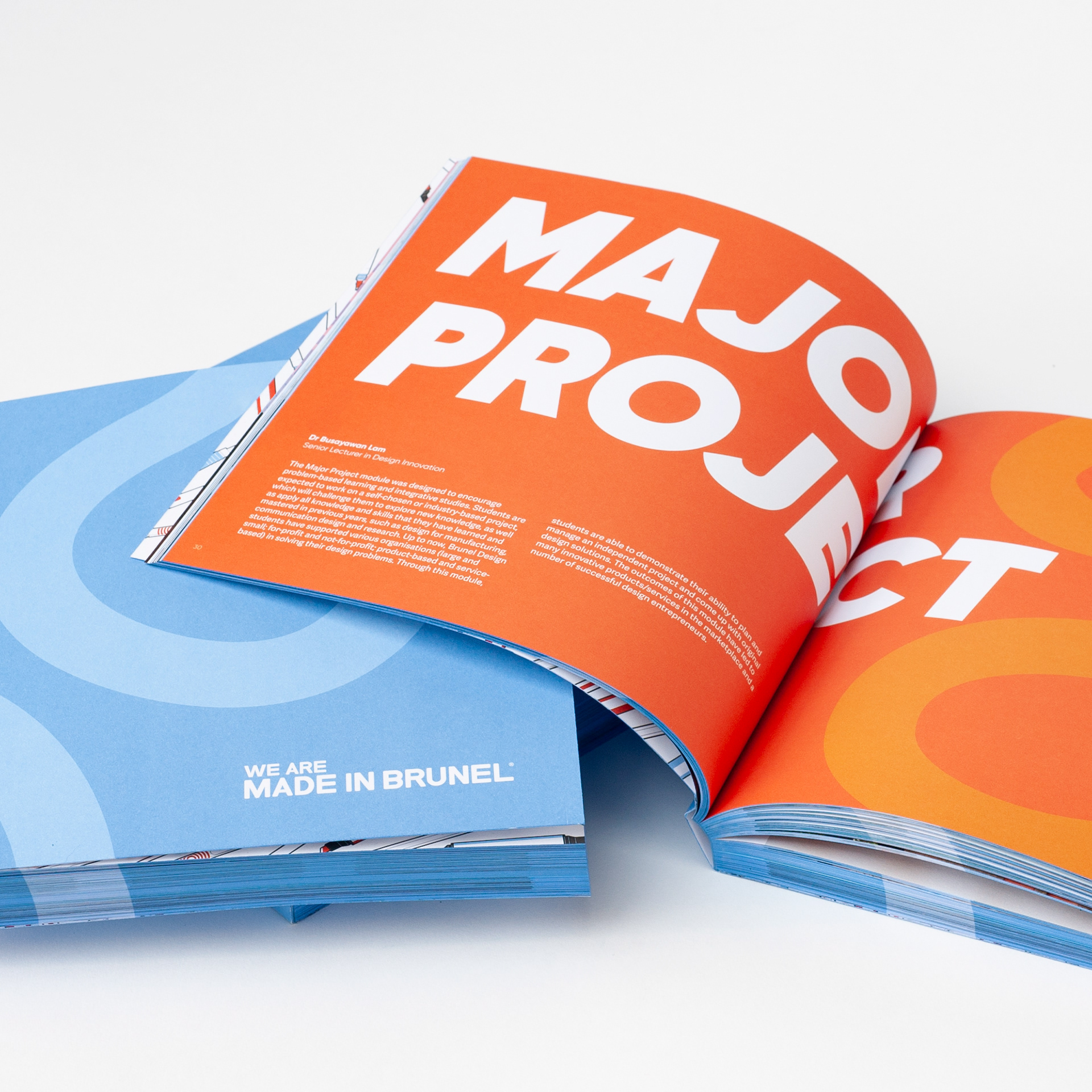

We Are Made in Brunel is a summary of the best design work to come out of Brunel University London in 2019/20. With 256 pages and over 150 contributors, my colleague and I oversaw production of the book from initial development workshops and concept creation, through the gathering of content and editing, to final proofing and distribution fulfilment.

As well as helping young designers to get their ideas seen, Made in Brunel is also an important promotional tool for the university itself, for both recruitment of prospective students and to further develop its relationship with the design industry. As such, the book was designed to be distributed to schools, industry and students, and to be understandable to all. This included features on the course structure, the placements and international exchanges available, the response to social issues, COVID-19 and the Black Lives Matter movement, and profiles of the university's partner organisations and programmes.

2020 posed some unprecedented challenges for Made in Brunel. The difficult graduate job market and cancellation of our usual degree show meant that the use of the book and online platforms to promote students' work was critical. The closure of the University and workshop facilities with projects unfinished prompted a much wider range of outcomes than in previous years, and a unique challenge finding a format that showed all student’s work fairly and its best. It also meant that almost the entire development process of the book was done remotely and often internationally, through hours of video calls, hundreds of emails and thousands of messages.

We Are Made in Brunel is also a study of efficiency vs effect. The production of a physical artifact over a digital one shows enormous faith and investment of the university in their own students, and the impact and longevity should not be understated. However with belts tightening, we were counting every penny to make sure this project could still happen. By working closely with the printers to reduce costs and even changing the page size for the most material efficient printing, the book was kept affordable while still keeping premium features such as foredge printing, PUR-OTA binding, and high quality litho printing on uncoated paper stock.